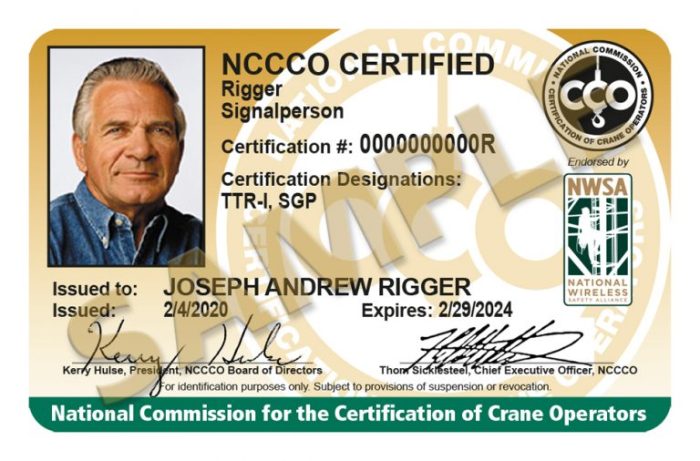

Nccco rigger 2 practice test – Embark on the journey towards NCCCO Rigger 2 certification with our comprehensive practice test. This meticulously crafted tool empowers you to sharpen your skills, assess your knowledge, and gain the confidence to ace the official exam.

Dive into a realm of rigging components, principles, safety protocols, and troubleshooting techniques. Our practice test mirrors the actual exam, providing a realistic simulation to prepare you for the challenges ahead.

Rigging Components and Equipment

Rigging involves using various components to assemble and support structures or systems. These components play crucial roles in ensuring the stability, safety, and functionality of the overall rigging setup.

Ropes

Ropes are flexible, high-strength cords used to lift, lower, or secure loads. They are available in different materials, such as nylon, polyester, and wire rope, each with specific characteristics and applications. Nylon ropes are lightweight, durable, and resistant to abrasion, while polyester ropes offer high strength and elasticity.

Wire ropes, made of steel or galvanized iron, are ideal for heavy-duty applications due to their exceptional strength and durability.

The nccco rigger 2 practice test can help you prepare for your certification exam. If you’re also interested in obtaining a CDL, be sure to check out the cdl air brake test ohio guide. Once you’ve mastered both exams, you’ll be well on your way to a successful career in the transportation industry.

To continue your preparation for the nccco rigger 2 certification, click here.

Cables

Cables are similar to ropes but are typically thicker and constructed with multiple strands of metal wire twisted together. They provide greater strength and stiffness compared to ropes, making them suitable for applications where high load-bearing capacity and rigidity are required.

Slings

Slings are specialized rigging components designed to lift and support loads. They are made of flexible materials, such as nylon, polyester, or wire rope, and are available in various configurations, including single-leg slings, double-leg slings, and choker slings. Each type of sling has specific load capacities and is used for different rigging applications.

Shackles

Shackles are U-shaped metal connectors with a removable pin or bolt that allows for easy attachment and detachment of rigging components. They are used to connect ropes, cables, or slings to other components, such as hooks, eyebolts, or load-bearing structures.

Shackles come in various sizes and load capacities, and their choice depends on the specific rigging application.

Rigging Principles and Techniques

Rigging involves the strategic positioning and arrangement of components, equipment, and personnel to safely and efficiently lift, lower, and secure loads. Understanding the fundamental principles and techniques of rigging is crucial for ensuring the safety and success of any rigging operation.

Load Distribution

Proper load distribution is vital in rigging. The load should be evenly distributed across all rigging components to prevent overloading and potential failure. This involves considering the weight of the load, the strength of the rigging equipment, and the angles at which the load is being lifted or lowered.

Balance and Stability, Nccco rigger 2 practice test

Maintaining balance and stability is essential in rigging. The load should be balanced both vertically and horizontally to prevent it from swinging or tipping. This is achieved by using multiple rigging points, adjusting the length of slings or ropes, and utilizing counterweights if necessary.

Hoisting Techniques

Hoisting involves lifting a load using a crane or other lifting device. The hoisting technique depends on the weight, size, and shape of the load, as well as the available equipment. Common hoisting techniques include single-point hoisting, multi-point hoisting, and tandem hoisting.

Lowering Techniques

Lowering a load involves carefully controlling its descent to prevent damage or injury. This is achieved by using controlled lowering mechanisms, such as hydraulic or electric winches, or by manually lowering the load with slings or ropes. Proper lowering techniques ensure the load is lowered safely and without causing damage.

Securing Techniques

Securing a load involves ensuring it remains stable and in place after it has been lifted or lowered. This is achieved by using a variety of techniques, such as tying off the load with ropes or chains, using chocks or wedges to prevent it from moving, and utilizing locking mechanisms to secure the load to the rigging equipment.

Safety Procedures and Regulations

Rigging operations involve inherent hazards that demand adherence to strict safety procedures and regulations. These measures safeguard personnel and prevent accidents, ensuring the smooth and efficient execution of rigging tasks.

Rigging hazards encompass various factors, including heavy equipment, suspended loads, and potential falls. To mitigate these risks, it is crucial to:

Pre-Operation Inspection and Planning

- Thoroughly inspect all rigging equipment, including ropes, slings, hooks, and shackles, for any signs of damage or wear.

- Carefully plan the rigging operation, considering factors such as load weight, rigging angle, and potential obstacles.

- Establish clear communication protocols among all personnel involved in the operation.

Safe Work Practices

- Use proper lifting techniques to avoid back injuries.

- Maintain a safe distance from suspended loads and avoid working underneath them.

li>Wear appropriate personal protective equipment (PPE), including hard hats, safety glasses, and gloves.

Emergency Preparedness

- Have an emergency plan in place to address potential accidents or equipment failures.

- Train personnel on emergency procedures and ensure they are familiar with the location of safety equipment.

- Conduct regular safety drills to enhance preparedness and response capabilities.

Adhering to these safety protocols and regulations is essential for minimizing risks and ensuring the well-being of all personnel involved in rigging operations.

Inspection and Maintenance

Rigging equipment is vital for the safe and efficient operation of cranes and other lifting devices. Regular inspection and maintenance are crucial to ensure the reliability and longevity of this equipment.

Thorough inspections help identify potential hazards early on, preventing accidents and costly repairs. Proper maintenance practices extend the lifespan of rigging components, reducing downtime and ensuring optimal performance.

Signs of Wear, Damage, or Corrosion

- Frayed or broken wires in wire ropes

- Cracks or deformations in hooks, shackles, and other metal components

- Excessive wear or pitting on sheaves and pulleys

- Rust or corrosion on any part of the equipment

- Loose or missing bolts, nuts, or pins

Proper Storage and Handling Techniques

Proper storage and handling practices are essential to preserve the integrity of rigging equipment.

- Store rigging equipment in a clean, dry, and well-ventilated area.

- Protect equipment from moisture, extreme temperatures, and direct sunlight.

- Avoid storing equipment on the ground or in areas where it may be exposed to corrosive substances.

- Handle equipment carefully to prevent damage from impact or excessive force.

- Follow the manufacturer’s instructions for proper handling and storage.

Troubleshooting and Problem-Solving

During rigging operations, various challenges and unexpected situations can arise. It’s crucial for riggers to possess the skills to identify and resolve these issues effectively, ensuring safety and efficiency on the job.

Common problems that may occur during rigging operations include:

- Equipment malfunctions or failures

- Load imbalances or instability

- Unforeseen weather conditions

- Communication breakdowns

- Human error or fatigue

To address these problems, riggers should follow a systematic troubleshooting approach:

- Identify the problem clearly and accurately.

- Determine the potential causes of the problem.

- Develop and implement solutions to eliminate the causes.

- Verify that the solutions have resolved the problem.

- Document the problem and its resolution for future reference.

Riggers can also benefit from sharing case studies or examples of how they have overcome rigging challenges safely and efficiently. This exchange of knowledge and experience helps the industry as a whole to improve practices and enhance safety.

Practice Test Questions

The NCCCO Rigger Certification Practice Test is a comprehensive assessment tool designed to evaluate your understanding of the key concepts and skills related to NCCCO rigger certification. The test covers a wide range of topics, including rigging components and equipment, rigging principles and techniques, safety procedures and regulations, inspection and maintenance, and troubleshooting and problem-solving.

The practice test consists of a variety of question formats, including multiple choice, true/false, and short answer. Each question is carefully crafted to test your knowledge and understanding of the subject matter. The test also includes answer keys and explanations for each question, so you can assess your progress and identify areas where you need additional study.

Question Format

- Multiple choice: Choose the best answer from a list of options.

- True/false: Indicate whether a statement is true or false.

- Short answer: Provide a brief answer to a question.

Topics Covered

- Rigging Components and Equipment

- Rigging Principles and Techniques

- Safety Procedures and Regulations

- Inspection and Maintenance

- Troubleshooting and Problem-Solving

Benefits of Taking the Practice Test

- Assess your knowledge and understanding of NCCCO rigger certification topics.

- Identify areas where you need additional study.

- Gain confidence in your ability to pass the NCCCO rigger certification exam.

Top FAQs: Nccco Rigger 2 Practice Test

What is the purpose of this practice test?

To prepare you for the NCCCO Rigger 2 certification exam by testing your knowledge and skills.

What topics are covered in the practice test?

Rigging components, principles, safety procedures, inspection, maintenance, troubleshooting, and problem-solving.

How many questions are on the practice test?

The number of questions may vary depending on the specific practice test you choose.